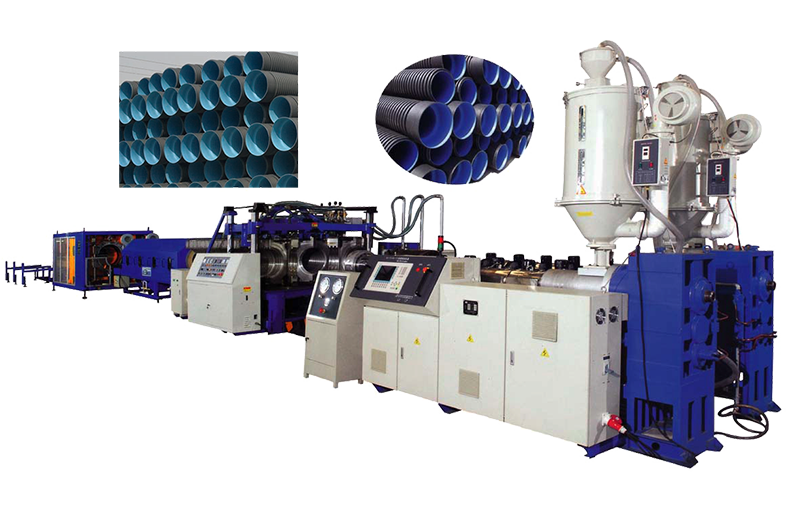

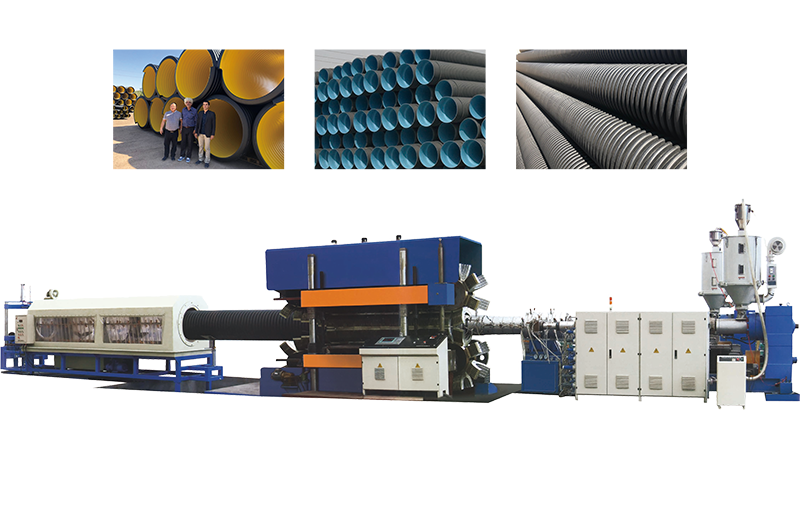

I-High Speed PE PP (PVC) Ulayini Wokunwetshwa Kwepayipi Elonakele

Incazelo

Umshini wamapayipi kathayela wePlastiki usetshenziselwa ukukhiqiza amapayipi kathayela epulasitiki, asetshenziswa kakhulu emithonjeni yamanzi yasemadolobheni, izinhlelo zokukhucululwa kwendle, amaphrojekthi omgwaqo onguthelawayeka, amaphrojekthi okunisela okongiwa kwamanzi emapulazini, futhi angasetshenziswa kumaphrojekthi okuthutha uketshezi lwamakhemikhali asemayini, enobubanzi obubanzi bezicelo. Umshini wokwenza amapayipi kathayela unezinzuzo zokuphuma okuphezulu, i-extrusion ezinzile kanye nezinga eliphakeme lokuzenzakalelayo. I-extruder ingaklanywa ngokuya ngemibandela ekhethekile yempahla yomsebenzisi, njenge-PE PP noma i-PVC. I-PE PP enodonga oluphindwe kabili kathayela ipayipi extrusion isebenzisa uhlobo olusha lwe-extruder yesikulufu esisodwa/esewele esisebenza kahle kakhulu. Umshini kathayela we-PVC usebenzisa iwele elikhulu eliyisicaba noma i-conical twin extruder. Ngesendlalelo esisodwa kanye nezendlalelo ezimbili zokuzikhethela. Ukwenza amapayipi kathayela aphindwe kabili, kunezinhlobo ezimbili,ovundlile kabili odongeni lukathayela extrusion umugqafuthimpo udonga lukathayela oluphindwe kabili lomugqa wokukhipha ipayipi.

Ukugeleza Kwenqubo

Izinto ezingavuthiwe → Ukuxuba → Isiphakeli Sevacuum →I-Plastic Hopper Drier →I-Extruder →Isikhunta Esikhiphayo →Isikhunta Esakha → Umshini Wokwenza Ukupholisa Amanzi →Fafaza Ithangi Lamanzi Okupholisa →umshini wokusika →Isitaki

Izici Nezinzuzo

1. I-HDPE yamukela uhlobo olusha lwe-extruder yesikulufu esisodwa/esewele esisebenza kahle kakhulu, futhi i-PVC yamukela i-extruder eyiwele elikhulu eliyisicaba noma i-conical twin extruder. I-extruder enkulu ye-twin-screw extruder noma i-parallel twin-screw extruder ingathola ukufakwa kwepulasitiki okuhle kakhulu kumazinga okushisa aphansi kanye ne-extrusion ezinzile.

2. Indlela yokupholisa imojula iphoqelelwa ukupholisa amanzi, okuthuthukisa kakhulu isivinini sokupholisa semodyuli, ukuze kuzuzwe ukukhiqizwa kwesivinini esikhulu.

3. Ulayini wamapayipi kathayela obuye ubizwe ngokuthi ulayini womshini wamapayipi kathayela owudonga oluphindwe kabili ungabona ukuvutha ku-inthanethi ukuze kuqinisekiswe ukuthi izici ezihlukahlukene zepayipi elakhiwe ziyahlangabezana nezindinganiso.

4. I-valve yokushintsha isilinganiso engenisiwe ilungisa ukwenza ingcindezi izinze futhi inokwethenjelwa.

5. I-Corrugator yohlobo oluvundlile

6. I-plateform esebenzayo iyakwazi ukulungiseka kathathu.

7. Uhlelo lokuvikela oluzenzakalelayo luyaqala futhi olusebenzisekayo luyabuya uma ucishiwe.

8. Isiteshi sokuthambisa esizenzakalelayo

9. Amabhulokhi esikhunta enziwe nge-aluminium alloy ekhethekile futhi afaka isisindo esilula, amandla aphezulu, ukumelana nokugqoka okuhle, ukusebenzisana okuncane kokunwetshwa okushisayo.

10. Ukupholisa komoya kanye nokupholisa amanzi ukuze kuphole kahle isikhunta sikathayela esenza ipayipi ngokushesha.

11. Umshini wokusika amapayipi kathayela unezinzuzo zokunemba okuphezulu futhi akukho uthuli.

12. Ulayini ophelele wamukela isistimu yokulawula ikhompuyutha encane ye-PLC engabonisa ngokubona izinga lokushisa elincibilikayo nokucindezela, ukwakha isivinini, i-alamu yephutha futhi inamandla okugcina enqubo eyisisekelo.

Imininingwane

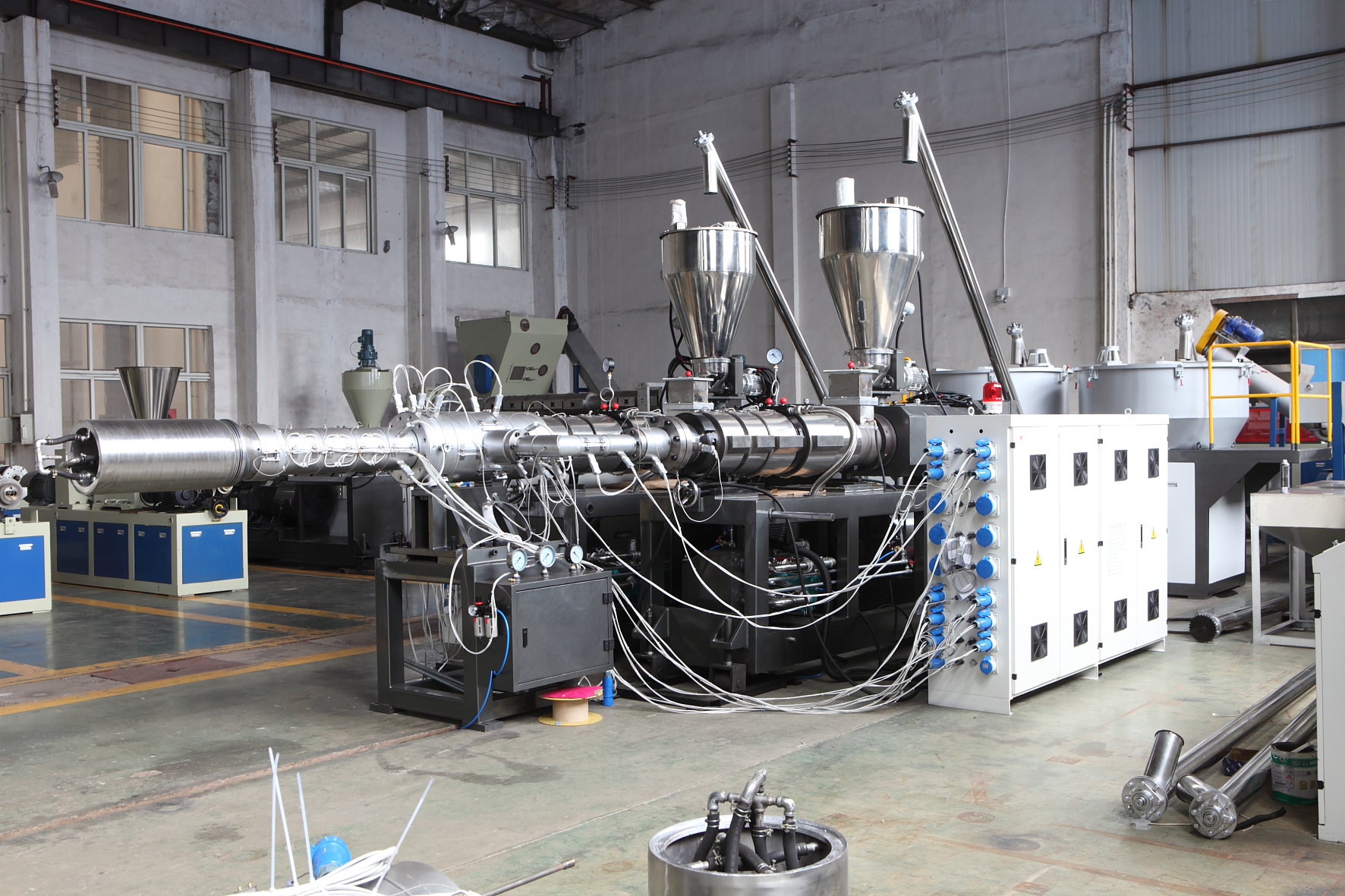

I-Single Screw Extruder ye-PE/PP

Ngokusekelwe ku-33:1 L/D isilinganiso sokuklama isikulufu, sithuthukise isilinganiso esingu-38:1 L/D. Uma kuqhathaniswa nesilinganiso esingu-33:1, isilinganiso esingu-38:1 sinenzuzo ye-100% yokwenza ipulasitiki, sikhulise umthamo wokukhipha ngo-30%, sinciphise ukusetshenziswa kwamandla size sifike ku-30% futhi sifinyelele cishe ukusebenza kwe-linear extrusion. Isilinganiso se-Adopt se-L/D esingu-38:1 isikulufu sento engakasetshenziswa kanye nesikulufu se-L/D 33:1 sezinto ezigaywe kabusha.

I-Simens Touch Screen ne-PLC

Faka isicelo sohlelo oluthuthukiswe inkampani yethu, ube nesiNgisi noma ezinye izilimi ezizofakwa ohlelweni.

Ukwakheka Okuvunguza Kwemigqomo

Ukondla ingxenye yomgqomo sebenzisa isakhiwo esivunguzayo, ukuqinisekisa ukudla okubonakalayo kuzinzile futhi kwandise umthamo wokudla.

Idizayini Ekhethekile Yesikulufu

I-Screw yakhelwe ngesakhiwo esikhethekile, ukuqinisekisa i-plasticization enhle nokuxuba. Izinto ezingancibilikisiwe azikwazi ukudlula le ngxenye yesikulufu.

I-Air Cooled Ceramic Heater

I-Ceramic heater iqinisekisa impilo ende yokusebenza. Lo mklamo owokwandisa indawo lapho i-heater ithintana nomoya. Ukuze ube nomphumela ongcono wokupholisa umoya.

I-Gearbox Esezingeni Eliphezulu

Ukunemba kwegiya kuzoqinisekiswa ibanga elingu-5-6 nomsindo ophansi ongaphansi kuka-75dB. Isakhiwo esihlangene kodwa esinetorque ephezulu.

I-Conical Twin Screw Extruder ye-PVC

Kokubili i-conical twin screw extruder kanye ne-parallel twin screw extruder ingasetshenziswa ukukhiqiza i-PVC. Ngobuchwepheshe bamuva, ukwehlisa amandla nokuqinisekisa umthamo. Ngokusho kwefomula ehlukile, sihlinzeka ngomklamo ohlukile wesikulufa ukuze kuqinisekiswe umphumela omuhle we-plasticizing kanye nomthamo ophezulu.

Isikhunta se-Extrusion

Kokubili ungqimba lwangaphandle kanye nongqimba lwangaphakathi kukhishwa ngaphakathi kwekhanda lokufa. Ishaneli ngayinye yokugeleza kwezinto ngaphakathi kwekhanda lokufa ibekwe ngokulinganayo. Isiteshi ngasinye singemva kokwelashwa kokushisa nokupholishwa kwesibuko ukuze kuqinisekiswe ukuthi izinto zihamba kahle. Futhi i-die head inikeza umoya ocindezelwe phakathi kokubili ungqimba. Umkhono wokulinganisa usetshenziselwa ukupholisa isendlalelo sangaphakathi ukwenza ipayipi elibushelelezi neliyisicaba ngaphakathi. Amanzi okucindezela ageleza ngaphakathi komkhono wokulinganisa ukuze abe nomthelela omuhle wokupholisa. I-vacuum yenziwa endaweni yomkhono wokulinganisa lapho ikhiqiza ipayipi elikhulu lobubanzi, qinisekisa ukujikeleza kwepayipi elingaphakathi.

Ukwakha Isikhunta

Imishini ye-CNC iqinisekisa ubukhulu obunembile. I-vacuum air duct kanye nesiteshi sokupholisa amanzi esine-flow cross-section enkulu siqinisekisa ukusebenza kokukhiqiza okuzinzile, okuseqophelweni eliphezulu, nokusebenza kahle. I-module ye-module i-aluminium alloy ephezulu, ene-conductivity ephezulu ye-thermal, ubulukhuni obuphezulu, nokumelana nokugqoka okuphezulu. Isakhiwo semojuli sisebenzisa inqubo yokufaka ingcindezi ebalulekile, enokwakheka okuminyene kanye nokuzinza okuphezulu kokushisa. Ukwelashwa kwangaphakathi kwemojuli kuthuthukisa amandla nobulukhuni bemojula, okusebenza kangcono ekwakhekeni okuphelele kwama-ripples. Isikhunta samukela imishini ye-CNC ukuze siqinisekise ukunemba kwayo nokusebenza kahle.

Ukupholisa amanzi Umshini wokwakha

Umshini wokwenza ukupholisa amanzi usetshenziselwa ukubeka nokuhambisa isikhunta sikathayela, i-vacuum iyakhiwa ukuze imunce ungqimba lwangaphandle lube isikhunta sikathayela ukuze kwakheke uthayela. Ngokuhambisa isikhunta sikathayela, ipayipi liphinde likhishwe kuthayela.

Automatic Lubrication System

Gcoba ngokuzenzakalelayo amagiya ukwenza isikhunta sikathayela sihambe kahle.

I-Transmission Gear Rack

I-gear rack ibekwe phezulu kwesikhunta sikathayela. Wonke ama-rack rack angemuva kokwelashwa kwe-nitriding nokushisisa, ukumelana nokugqokwa isikhathi eside.

Uhlelo Lokulungisa Oluphezulu

Lungisa nge-elekthronikhi uhlaka olungaphezulu losayizi ohlukile wesikhunta sikathayela. Ngezinsika ezine, qinisekisa ukulungiswa okuzinzile nokunembile.

I-Tension Adjusting System

Ukuze ulungise ukushuba kokuhamba kwesikhunta, yenza isikhunta sihambe kahle.

I-Proportional Valve

Ukulawula umoya uzinze kakhudlwana futhi unembile, ukwakha ipayipi elihle kanye nesimo sesokhethi.

Isikhunta Ukupholisa System

Ngazo zombili izinhlelo zokupholisa amanzi kanye nesistimu yokupholisa umoya, ukuze ube nomphumela ongcono wokupholisa, ukwakheka kwamapayipi amahle futhi asheshayo.

I-UPS Backup Power

Uma amandla ehluleka, amandla ayisipele samandla e-UPS azonikeza amandla kuthayela ukuze kukhishwe ipayipi kumkhono wokulinganisa. Ukuze ugweme ukunamathela kwepayipi kumkhono wokulinganisa ngemva kokupholisa kwepayipi kanye nokuncipha.

Futha Ithangi Lamanzi Okupholisa

Ithangi lokupholisa lisetshenziselwa ukupholisa ipayipi ngokuqhubekayo.

I-Axiliary Haul-off

Ngedivayisi yokudonsa eyisizayo, nedivaysi yokudonsa iyavumelana nezimo. Ukudonsa ipayipi ngokuqhubekayo.

Quality Spray Nozzle

Imilomo yesifutho yekhwalithi inomphumela opholile wokupholisa futhi akulula ukuvinjwa ukungcola.

Isihlungi Sethangi Lamanzi

Ngesihlungi ethangini lamanzi, ukugwema noma yikuphi ukungcola okukhulu lapho amanzi angaphandle engena.

Umshini wokusika amapayipi kathayela

Umshini wokusika amapayipi kathayela ukunemba okuphezulu futhi akukho uthuli.

Idivayisi ye-Aluminium Clamping

Faka i-aluminium clamping device kumasayizi amapayipi ahlukene. Usayizi ngamunye onomshini wokunamathisela owakhe, asikho isidingo sokushintsha ukuphakama okumaphakathi nendawo uma kumasayizi amapayipi ahlukene.

Isistimu yokuvumelanisa

Isiteshi sokusika siqhutshwa yi-motor kanye ne-inverter. Ngesikhathi sokusika, isiteshi sokusika sihamba ngokuhambisana ne-corrugator ukugwema ukuguqulwa kwamapayipi.

Ukusika Ummese Kabili

Ngemimese emibili esika ndawonye, ukuqinisekisa ukuthi ingxenye yesiphetho sesokhethi inqunywe ngokuphelele.

Isitaki

Ukusekela nokwehlisa amapayipi. Ubude besitaki bungenziwa ngendlela oyifisayo.

Ukusekela nokwehlisa amapayipi. Ubude besitaki bungenziwa ngendlela oyifisayo.

Ukuze sihambise ipayipi likathayela ngokushelela ku-stacker, sisebenzisa insimbi engagqwali yonke phezu kwesitaki.

Ukugoqa ipayipi ku-roller, kulula ukuyigcina nokuhamba. Ivamise ukusetshenziselwa ipayipi elingaphansi kuka-110mm. Yiba nesiteshi esisodwa kanye nesiteshi esiphindwe kabili ongasikhetha.

Idatha Yezobuchwepheshe

| Imodeli | Usayizi wepayipi(mm) | I-Extruder | Okukhiphayo(kg/h) | Isivinini(m/min) | Amandla aphelele(KW) | Isikhunta(amapheya) | Isistimu yokupholisa |

| SGB250 | 90-250 | SJ65 SJ75 | 300 | 1-4 | 150 | 48 | Ukupholisa umoya nokupholisa amanzi |

| SGB500 | 200-500 | SJ75 SJ90 | 600 | 1-4 | 200 | 40 | Ukupholisa umoya nokupholisa amanzi |